Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

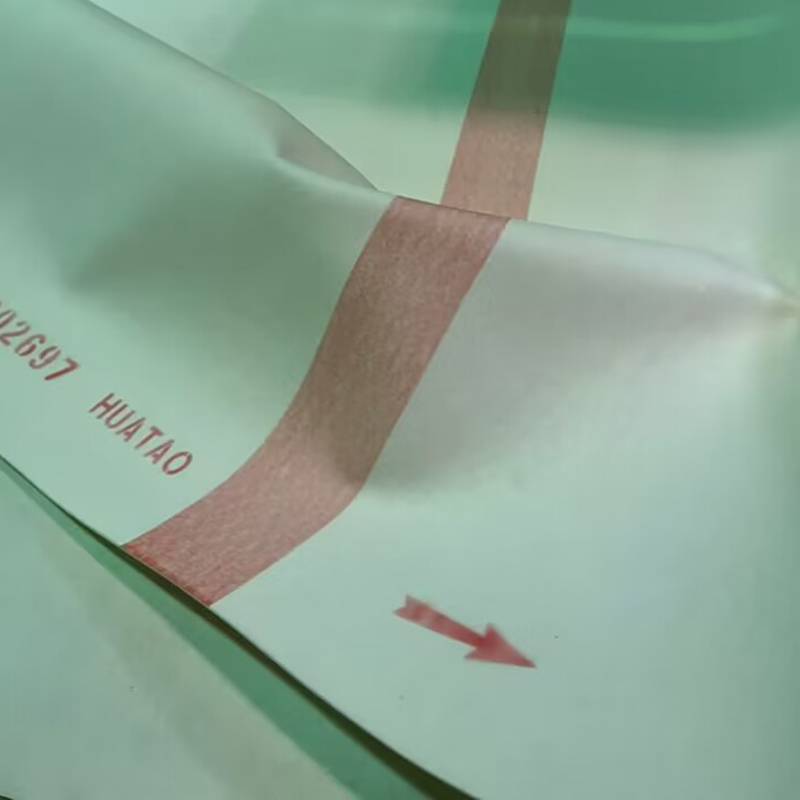

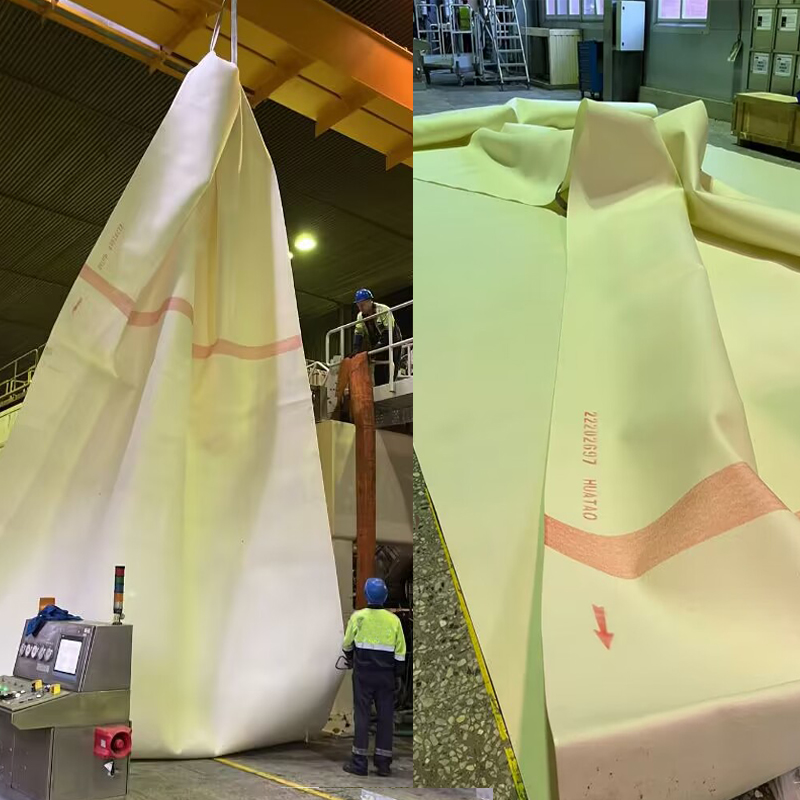

Our Combi Press Top & Bottom Felt was successfully installed and running for more than 30 days. For Combi Papermaking Felt, you could choose our 1800GSM Endless seam felts, and for the Shoe Press, please select 2000GSM Seamed Felt. The Felt seam joint could be installed within 30mins, highly saving maintenance time and reducing downtime loss.

The felt has a good performance on the paper machine that produces linerboard 125-175 gr / m2 at 800m/min working speed and produces 160-280 gr/m2 gypsum board at 500--600m/min.

See its features and benefits as follows:

Hybrid construction: Combi felts are constructed using a combination of different materials, such as synthetic fibers and traditional materials like wool or cotton. This hybrid construction allows them to provide superior performance characteristics that are tailored to various paper grades and machine configurations.

Optimized Surface Properties: Combi felts are designed to have specific surface properties that optimize water drainage and paper surface smoothness. These felts help to achieve uniform dewatering, reduce sheet marking, and enhance paper formation.

Enhanced Durability: The use of modern synthetic fibers in Combi felts enhances their wear resistance, extending their lifespan and reducing the frequency of replacements. This contributes to reduced downtime and maintenance costs.

Consistent Performance: Combi felts are engineered to maintain consistent performance over a longer period of usage. This ensures that the quality of the paper produced remains stable throughout the production run.

Customization: Manufacturers can tailor Combi felts to specific paper grades and machine conditions, allowing for optimization of dewatering efficiency, moisture control, and paper properties.

Improved Runnability: The design of Combi felts reduces the risk of edge flutter and wrinkling, leading to smoother machine operation and fewer production interruptions.

Reduced Energy Consumption: The optimized drainage properties of Combi felts can contribute to more efficient dewatering, reducing the energy required for subsequent drying stages of paper production.

Environmental Considerations: Combi felts often incorporate eco-friendly materials and production methods, aligning with sustainable practices within the paper industry.

Compatibility: Combi felts are engineered to be compatible with modern high-speed paper machines, ensuring they can withstand the demands of rapid production while maintaining performance.

Application: Combi felts are typically used in the press section of paper machines, where they come into contact with the paper sheet and aid in water removal, sheet consolidation, and the transfer of the paper web through the press rolls.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.