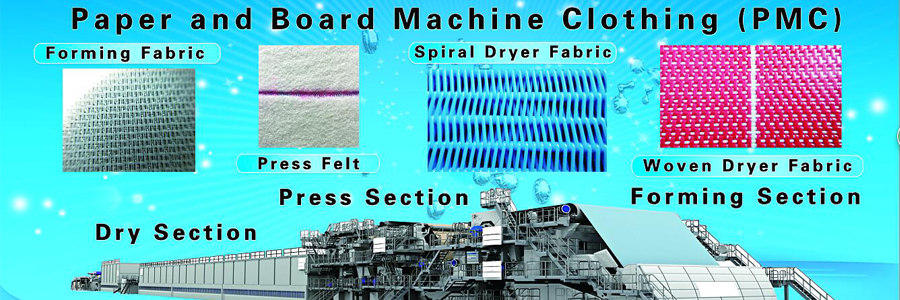

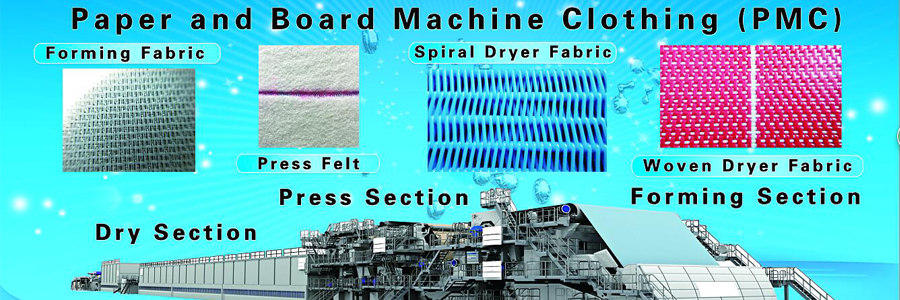

paper machine Polyester Paper Machine Clothing

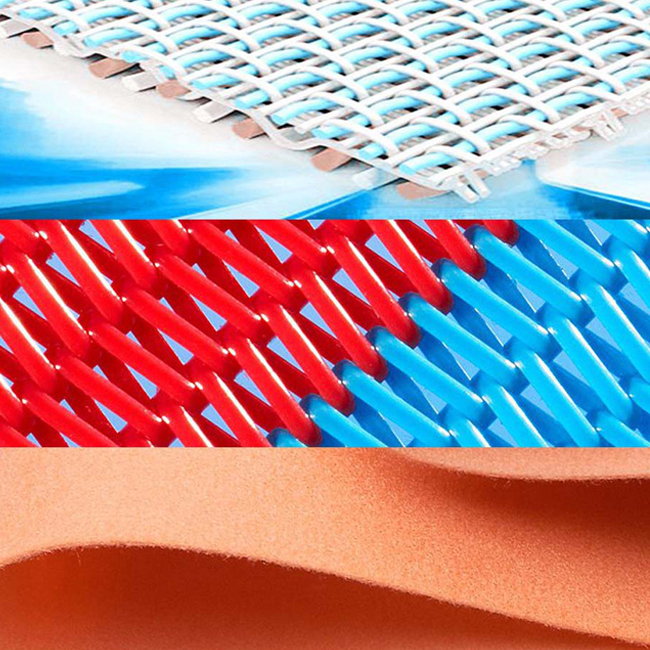

forming fabric / Forming Wire

In the forming section of the paper machine, a mixture of approximately 99% water and 1% cellulose fibers and filler material is introduced uniformly across the width of the forming fabric. During this process, the forming fabric acts as both a Conveyor Belt and a dehydrator. When the fabric moves quickly, more than 96% of the water is drained through the special voids in the fabric, while the fibers and fillers remain on top of the fabric to form a paper sheet structure. Huatao has constantly improved their forming fabric technology and created fabrics providing excellent runnability, high wear resistance, long running time, good paper profiles and good retention.

4-shed single layer forming fabric is standard type of polyester forming fabric in paper making, mainly used for producing cultural paper printing paper, packing paper and so on.

5-shed single layer forming wire is suitable for making healthy, culture and packing papers etc.

8-shed single layer forming fabric is the most wear-resisting one in the single layer screen, which have long performance life, but mesh print is relatively deep. It is mainly used for copying the papermaking bag, craft paper, Cardboard , corrugated paper and so on.

7-shed double layer forming fabric is suitable for quality printing paper and tissue paper etc.

8-shed double layer forming fabric is suitable for quality printing paper, tissue paper and the surface pulp and inner pulp of the board paper etc.

8-shed, 16-shed double and a half layer forming fabric is suitable for making quality printing paper, tissue paper and surface pulp, inner pulp and base pulp of the board paper etc.

Multi-shed SSB three-layer forming fabrics suitable for making quality printing paper, tissue paper and cigarette paper etc.

Forming Fabric Application Paper Machine Type

1. Fourdrinier Paper Machine

2. Twin Wire Former Paper Machine

3. Crescent Tissue Machine

4. Pulp Drying Machine

Forming Fabric Feature & Advantage

1. Excellent drainage capacity

2. Improve fiber retention

3. Long lifetime and better dimensional stability

4. Better running stability and abrasion resistance

5. Ease of maintenance

6. Professional design

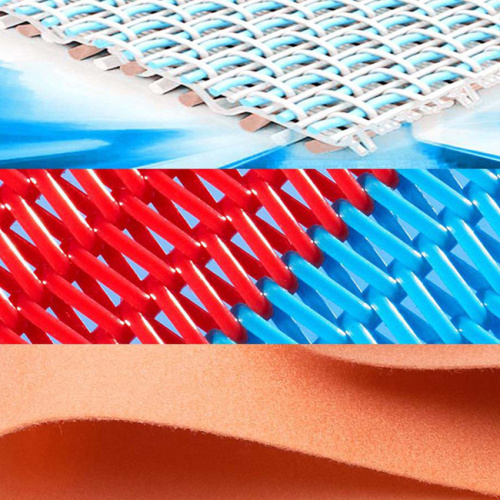

Dryer Screen / dryer fabric

Dryer fabric in papermaking serves two functions. First, it removes the remaining water in the web that cannot be removed by vacuum or pressing. Second, it causes fibres to bond together by hydrogen bonding.

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders, dryer fabric threaded in it to press the paper onto the hot rolls. The Dryer fabric mainly use in Packing paper machine, Culture paper machine, Specialty paper machine.

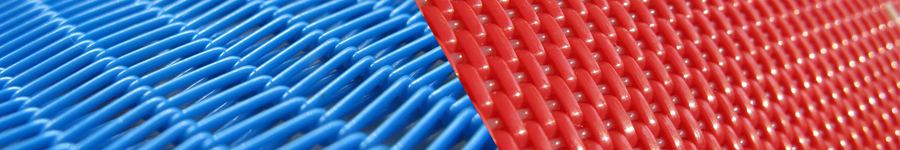

Huatao dryer fabrics are mainly divided into two series: spiral dryer fabrics and woven dryer fabrics, product range covers all the dryer fabrics needed on paper and board machines. The polyester dryer fabrics are for normal paper machine conditions, whereas the PPS reinforced dryer fabrics are for hydrolysis-prone positions where high steam pressures are used.

Woven Dryer Fabric

3-shed one layer and a half polyester dryer fabric are suitable for drying papers below 70g.

4-shed double layer polyester dryer fabric is suitable for drying papers above 70g.

Rectangular wire polyester dryer fabric is suitable for the fore several heating box of the drying zone, quality papers can use all.

Spiral Dryer Fabric

Polyester Spiral Desiccation Mesh is widely used in producing of paper, corrugated paper, paper for train fare, also used in filtration and sieving in environmental protection, pharmaceutical, mine, metallurgy, machinery, airspace and other fields.

Major Use of polyester spiral belt:

Producing of paper, corrugated paper, paper for train fare.

Filtration and separation of air, liquid and solid in various fields

Dryer Fabric Features

1. High operating efficiency: less paper breaks, reducing the times of temporary shutdowns.

2. High heating transfer efficiency: High contact surface area and good heating transfer effect with increased ventilation, energy saving.

3. Long lifetime: resistance to hydrolysis, excellent wear and jam resistance.

4. Easy installation: prefect seam and seaming aids.

1. Good dimensional stability, Easiness to clean, Flexible and strong edge Reinforcement .

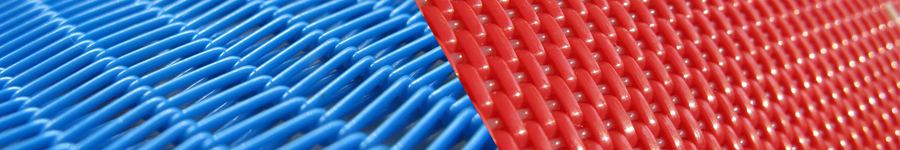

Paper Machine Felt / Press Felt

Press felts play an important role in removing moisture from the paper web after the forming section, while imparting smoothness and transporting it to the dryer section. To this end, press felts need to provide the following functions: water removal, smoothing and runnability.

According to the location on the paper machine can be divided into wet felts, top Felt and dryer felt. The function of the Wet felt is to press the raw paper to make it dehydrated and smooth the paper surface. The top felt is used above the wet felt and plays the role of leading, flattening paper and drying. Dryer felt wraps the Dryer Cylinder to iron and dry the paper.

Paper Machine Felt Features

1. The dehydration rate of press felts is very high. High anti-compaction capacity.

2. Smooth and compact press felts surface, Extremely high elasticity, and recoverability.

3. Press felts are easy to maintain a clean structure; no stickiness, no uneven clogging.

4. The total energy consumption of press felts is low. Strong drainability and larger void volume.

5. Long holding time of wear resistance and plastic strength of felt.

6. Smooth felt surface and even pressure distribution.

Feature Of Seam Press Felt

1. Easy to seam on the machine.

2. Safe, easy and quick installations decrease the need of manpower and crane time, and thereby.

3. Increase the efficiency of the shut down time.

4. Durable structure with strong and non-marking seam area.

5. Good resistance against compaction and filling.

6. Good water handling capacity

Our team of senior engineers can organize the best commodity source for you. By supplying the best Chinese products, Professional design and responsible attitude on service,we devote to creating our unique brand "HUATAO" in global. Since the establishment, " HUATAO " products have been supplied to more than 20 countries and set up the agencies. And our products and service have been recognized and trusted by the end users all the way. We believe, once we have the cooperation, "HUATAO" will be your most reliable partners in your road to success. Because of trust , business will be simple.