Large Flow Vertical Sewage Screw Pump

$2000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao ,Tianjin |

$2000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,CIP,DAF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai ,Qingdao ,Tianjin |

Model No.: HT - Large Flow Vertical Sewage Pump

Brand: HUTAO

Working Temperature: -30 Degree Centigrade to 220 Degree Centigrade

Seal: Mechanical Seal

Large Flow Vertical Sewage Pump

Screw Pump Introduction

Large Flow Vertical Sewage Pump is a vertical sewage pump specially designed for handling large volumes of sewage. The pump adopts high-efficiency sewage treatment technology, which can quickly and effectively discharge sewage into the sewage treatment system. Its vertical structure design can complete a large amount of sewage treatment in a small space, suitable for sewage and wastewater treatment in industrial and municipal fields. The pump is made of high-quality stainless steel or other high-performance alloy materials, featuring wear resistance, corrosion resistance, high strength and long life. It is designed for non-clogging, low noise, high efficiency and reliability, and can adapt to different sewage treatment requirements. It is ideal for the treatment of large volumes of sewage, providing efficient and reliable solutions for industrial and municipal environmental protection, ensuring the cleanliness and health of factories and communities.

Screw-type Pump Advantages

1.High Efficiency: Double screw Pumps are highly efficient, with low energy consumption and minimal losses due to friction. This makes them an ideal choice for applications where energy efficiency is a concern.

2.Consistent Flow: Double screw pumps provide a consistent flow rate, even when handling fluids with varying viscosity. This is because the screw geometry creates a continuous flow path, which eliminates pulsation and ensures a steady stream of fluid.

3.High Pressure Capability: Double Screw Pump is capable of generating high discharge pressures, making them ideal for applications where high head is required.

4.Minimal Maintenance: Double screw pumps have a simple, robust design that requires minimal maintenance. They have fewer moving parts than other pump types, reducing the risk of failure and extending the pump's service life.

5.Versatility: Double screw pumps can handle a wide range of fluid viscosities, from thin liquids to highly viscous materials. They can also handle abrasive and corrosive fluids, making them a versatile choice for a range of industrial applications.

6.Low Noise and Vibration: Double screw pumps operate quietly and with minimal vibration, reducing the risk of damage to surrounding equipment and creating a more comfortable working environment.

Single Screw Pump Operation Principle

A Screw Pump is a type of positive displacement pump that uses one or more screws to move fluids through a system. The screw(s) rotate in a cylindrical chamber, and as they turn, they trap fluid and move it from the inlet to the outlet of the pump. Screw pumps are known for their ability to handle a wide range of fluids, including high viscosity liquids, slurries, and liquids with solid particles. They can also operate at high pressures and with low pulsation, making them a popular choice for many industrial applications.

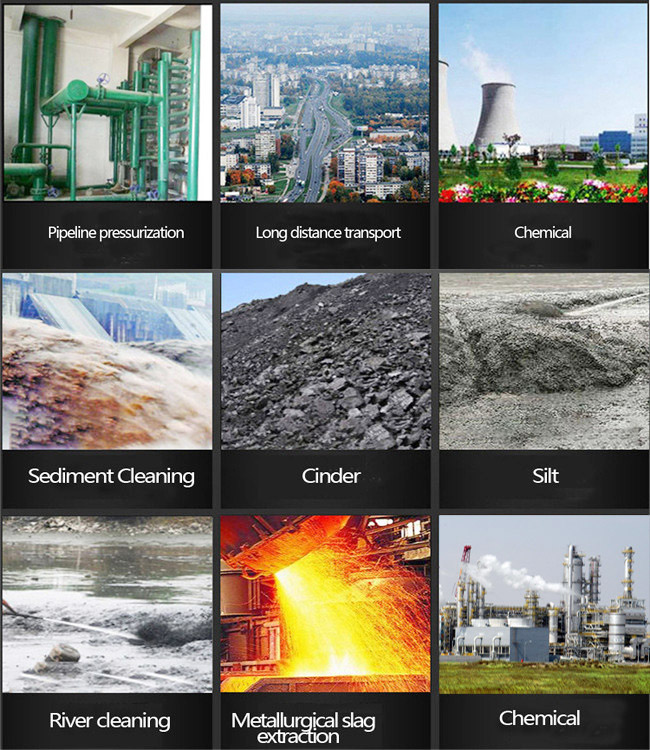

Progressing Cavity Pump Application

Slurry Screw Pump Specification

| Product Name | Screw pump |

| Voltage | 220V / 380V |

| Flow | 10~90m3/h |

| Suction Diameter | 3~6 inch |

| Head | 1~ 99m |

| Power | up to 120 kw |

| Material | Cast iron/Stainless Steel(SS304/SS316L/SS904) |

| Warranty | 1 year |

Huatao Pumps Application

Huatao Pumps Package, Shipment, Workshop

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.