Paper Mills Pulp Making Disc Heat Disperser Machine

$3000-20000 /Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | SHANGHAI,TIANJIN,Beijing |

$3000-20000 /Set/Sets

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Air |

| Port: | SHANGHAI,TIANJIN,Beijing |

Model No.: Floatating-Dispersering-Bleaching Equipment

Brand: HUATAO

Status: New

Warranty Period: 1.5 Years

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Voltage: 380V 50HZ

Type: Pulping Equipment

Computerized: No

Power(W): 200-1250kw

Dimension(L*W*H): As Per Model

Function: Deinking From Paper Pulp

Rotational Speed: 1480(r/min)

Inflow Pulp Consistency: 30-35%

Body Material: Carbon Steel Or Stainless Steel 304

Applicable Industry: Manufacturing Plant

Out-of-warranty Service: Video Technical Support, Online Support

Paper Pulp Making Disc Heat Disperser Machine For Paper Mill

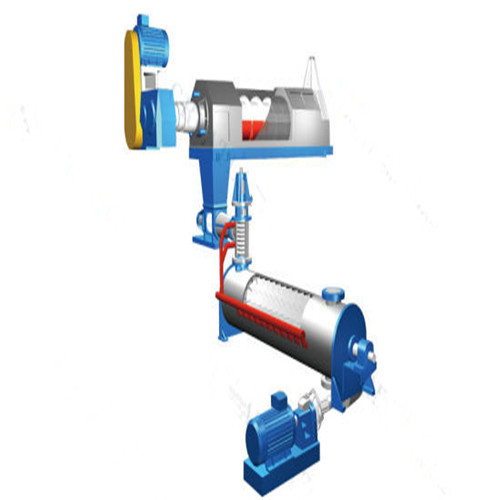

Disc Heat Disperser Introduce

The disc heat dispersing system is suitable for various slurry treatment with waste paper as the basic raw material. It can effectively disperse impurities such as stickies, grease, paraffin, plastic, and ink particles in the waste paper slurry to improve Improve paper quality and improve paper performance.

The system mainly includes: slurry thickening equipment (twin-wire double-press squeezer or oblique screw squeezer and screw squeezer), plug screw, crushing screw, preheater, and disc heat disperser. The heat dispersion system adopts PLC automatic control with high control precision.

Use thickening equipment to increase the concentration of the slurry to about 30%, send it to the heat dispersion system, use the plug screw conveyor to prevent steam from escaping, use the shredder to break up the slurry, and use the heater to heat the slurry. Type thermal dispersion for dispersion treatment.

Disc Heat Disperser Application

Disc heat disperser, it is one of the indispensable equipment in the pulping and papermaking process using waste paper as raw material. Large ink dots, etc., to ensure more economical and effective production of high-quality recycled pulp. This equipment has the advantages of less fiber cutting, good dispersion effect, no need for disc grinding and beating, and low operating costs. It is suitable for all kinds of waste paper pulping.

HUATAO GROUP CO. specialize in the Pulp * Paper Industry since 2008, could also supply follows,

1. paper machine Clothings

2. Paper Machine Wire Section Renovation : headbox suppliers/factory, high-quality products of Pressurized Former R & D

4. Paper Machine Rolls

5. Pulper Equipments

6. Spare Parts Of Pulping Equipment

7. Screening And Cleaner

8. Thickner And Washer Equipment

9. Refiner Or Defibering Equipment

10. Floatating-Dispersering-Bleaching Equipment

11. Agitator And Pulp Pump

12. Paper Machine Finished Equipment: Slitting And Reqinding Equipment, Jumbo Roll Paper Slitting Mahcine suppliers/factor

If any spare parts interested, welcome to contact HUATAO GROUP to get more details.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.